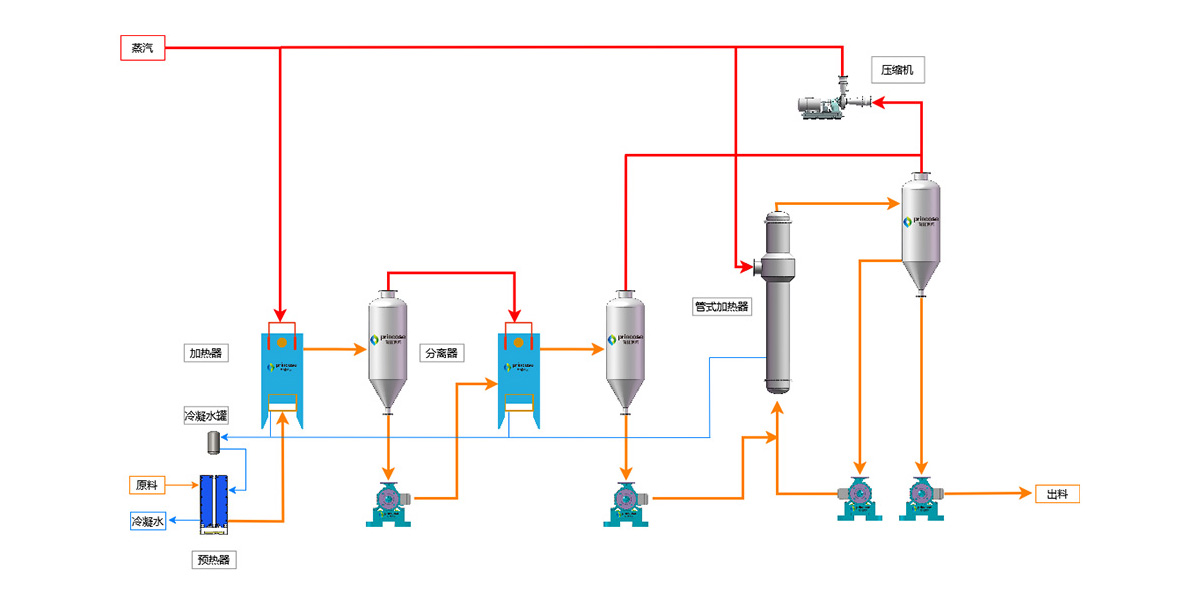

The MVR technology is skillfully combined with plate preheaters and tube heat exchangers to form a unique evaporative crystallization system. The plate preheater utilizes its efficient heat transfer performance to preheat the material; The tubular heat exchanger further ensures the evaporation and crystallization process of materials through its stable heat transfer effect. The plate-tube combined MVR evaporator can be combined into double-effect, triple-effect, quadruple-effect, etc. The system operation mode can be manual, semi-automatic, fully automatic, etc.

The biggest feature of multi-effect evaporator is its high efficiency and energy saving. By fully utilizing the energy of secondary steam, the energy consumption of multi-effect evaporators is more than 30% lower than that of single-effect evaporators.

The structure of the multi-effect evaporator is relatively compact, with a small footprint. Due to its use of a multi-stage evaporator in series, the equipment is smaller in size, which allows it to better coordinate with other equipment during production and improve production efficiency.

The multi-effect plate-tube evaporator is equipped with an automated control system, making operation simple and convenient.

Rich experience in process planning and equipment manufacturing

Customized Process Solutions

The project scope ranges from experimental testing of material parameters, to determination of process plans, to drawing, procurement, manufacturing, installation, debugging, training, and ultimately equipment delivery

Career

Professional

build Brilliant

Future

Proficient in industry/Achieving the future