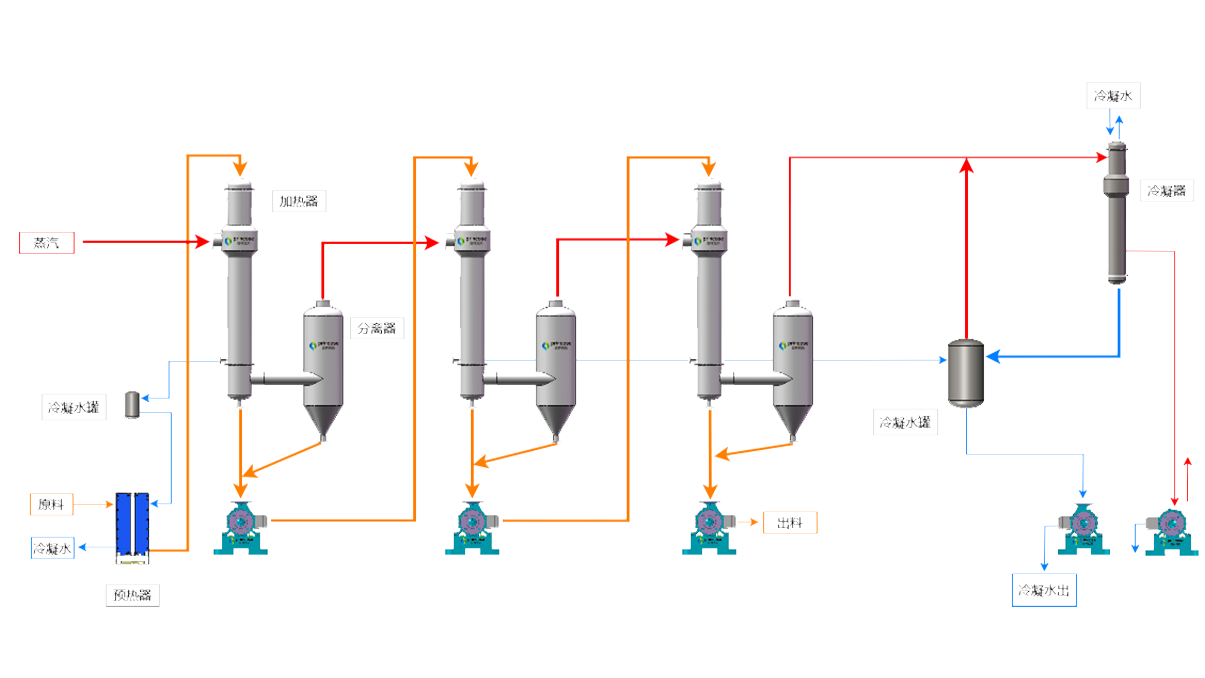

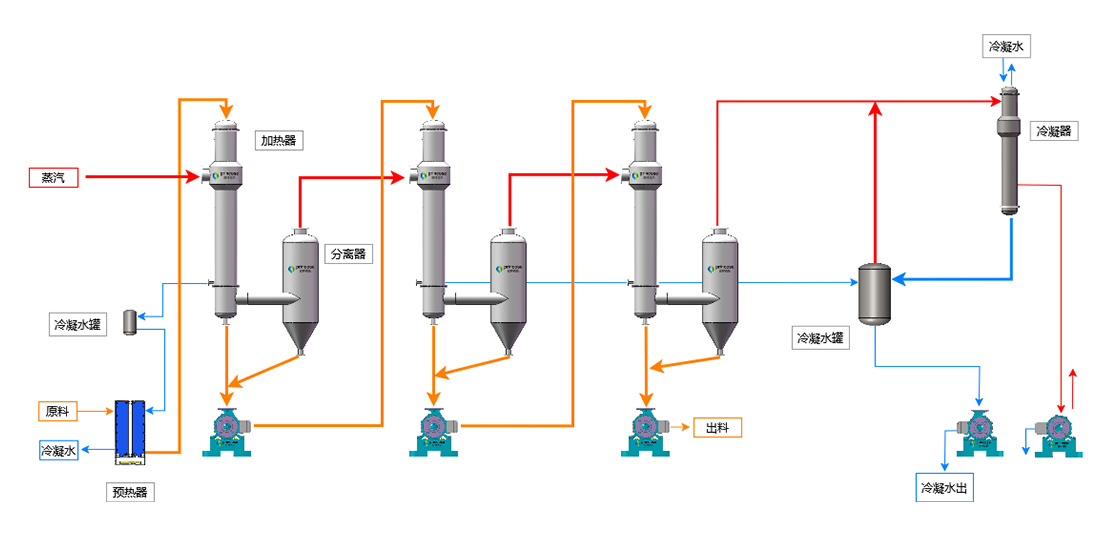

The tubular multi-effect evaporation system operates by utilizing the secondary steam from one effect as the heating steam for the subsequent effect in a tandem evaporation process, enabling multiple utilizations of thermal energy. In multi-effect evaporation, the operating pressure of each effect, the corresponding heating steam temperature, and the boiling point of the solution decrease sequentially. Through this method, the tubular multi-effect evaporation system can significantly enhance evaporation efficiency and reduce energy consumption.

The material is preheated through a preheater before entering the evaporator.

Inside the evaporator, the material exchanges heat with heating steam and evaporation occurs. The gas-liquid mixture then enters a separator for gas-liquid separation.

The generated secondary steam is compressed by a compressor to increase its pressure and temperature.

The compressed steam is sent back to the evaporator to serve as heating steam, achieving cyclic utilization.

Due to the graded utilization of thermal energy, the tubular multi-effect evaporation system can significantly reduce the consumption of fresh steam, thereby lowering energy consumption.

Adopting the tubular heat exchanger structure results in a relatively small evaporator volume, making the entire system occupy a smaller footprint.

The system employs an advanced automated control system, enabling remote monitoring and operation, which reduces the difficulty and labor intensity of manual operation.

The tubular multi-effect evaporation system is suitable for treating various types and concentrations of solutions, demonstrating strong adaptability and flexibility.

Career

Professional

build Brilliant

Future

Proficient in industry/Achieving the future